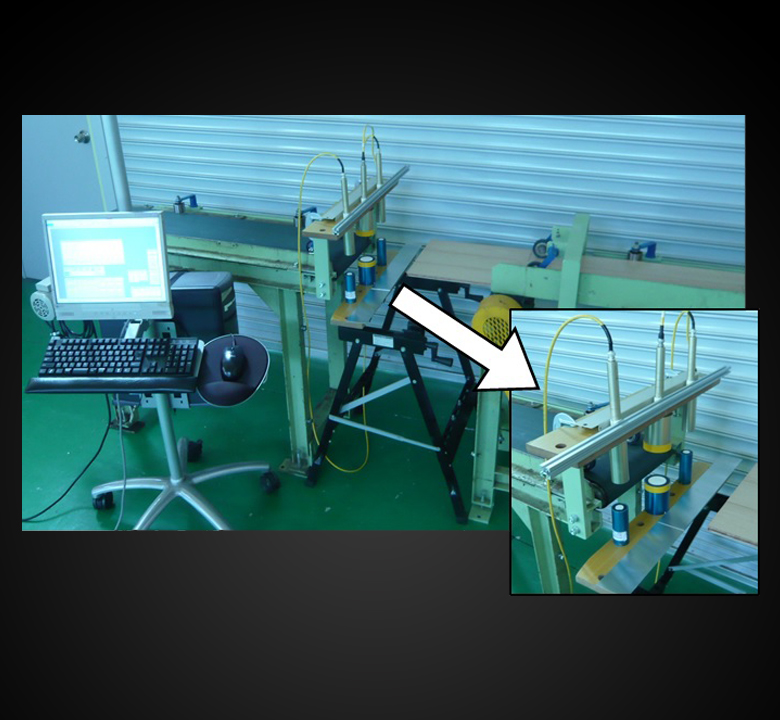

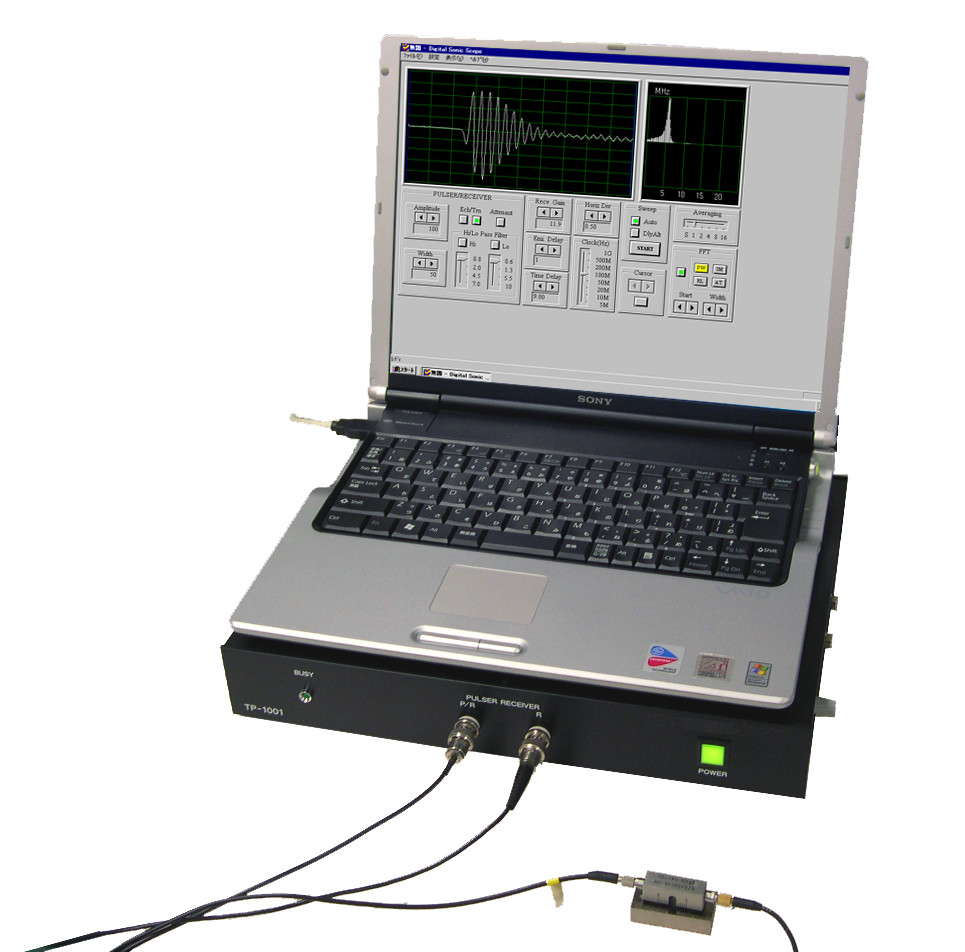

Pulsar Receiver (GNES-1001-PR)

Table

| Bandwidth | from 300Hz to 20MHz (±3dB) |

| Pulse output | Maximum 600 V (10 V Step) |

| Sampling frequency | from 0.5MHz to 100MHz |

Strength

USB compatible: Easy connection to the notebook PC, Windows standard software is initialized, easy to operate and waveform analysis is possible.

Measurable parameters

Ultrasonic measurements such as sound velocity and attenuation,

Film thickness, calibration curve measurement such as degradation diagnosis,

As an option,

Elastic modulus measurement, thickness measurement, bolt axial force measurement

Applicable field

- Materials

Dry-Coupling Sheet

It is a low damping material that can be used for the couplant without using a liquid couplant. As a result of flaw detection, 15 MHz probe with delay line can be used in the flaw detection.

Strength

- It can be processed freely because it is a sheet type.

- It can be used in the porous body which permeates gel-like couplant, it is effective for stable experiments.

- It is inexpensive, and can order from 1 piece.

Lineup

| Size: | 150mm×150mm, 300mm×300mm |

| Thickness : | about0.5mm, 1.0mm, 2.0mm |

| Hardness: | 40, 50 |

Applicable field

- Materials

- Others

G-Sonic Couplant

It is an oily couplant that can also transmit transverse waves (shear vibration) and can be used as a transverse wave couplant for ultrasonic flaw detection.

In addition, it can be used for a long time as a couplant for ultrasonic flaw detection with less sensitivity drop due to moisture absorption.

Strength

- It can be used for specimens that cannot use liquid couplant such as water, machine oil, glycerin paste.

- It can be used for rough surface material.

Lineup

SH – L: Low viscosity type, 100g

SH – H: High viscosity type, 150g

Applicable field

- Others

Air-coupled (non-contact) Ultrasonic Testing System (In-line type)

Existing ultrasonic testing methods require contact medium like water to transmit ultrasonic waves to scan objects, but water or oil cannot be used for a scan object for which rust or deterioration is concerned. Using low frequency probes, high power pulser/receivers, signal amplifier and noise filters, air-coupled ultrasonic testing becomes possible without contact medium.

Just install onto the production conveyor a mount fixing multiple probes arranged in parallel to enable automatic scanning of flaws inside of steel plates, board shape construction materials and so on.

Click here to download the brochure.

Strength

With the software to describe C-scope (2 dimensional graph with wave form data for each XY cordinate point), OK/NG judgment and description of flaw position/distribution is possible. Just install onto the production conveyor a mount fixing multiple probes arranged

in parallel to enable automatic scanning of flaws inside of steel plates, board shape construction

materials and so on.

Applicable field

- Building materials

Ultrasonic Elastic Modulus Measuring Device (UMS-H/R)

Property values unique to each material are calculated by measuring reflection time when ultrasonic wave is transmitted into a test piece. With a flat space to attach the probe, not only a test piece but also a product can be measured. Measurement values are longitudinal wave velocity, horizontal wave velocity, young’s modulus, rigid modulus, bulk modulus, compressive elastic modulus, poisson ratio, lamé parameters, anisotropy of the sound velocity, Debye temperature and others.

Click here to download the brochure.

Measurable parameters

Sonic speed, Young’s modulus, rigidity factor, bulk modulus of elasticity, compressibility, Poisson’s ratio, Lame parameter, sound velocity anisotropy coefficient, longitudinal and transverse wear, Debye temperature.

Applicable field

- Materials

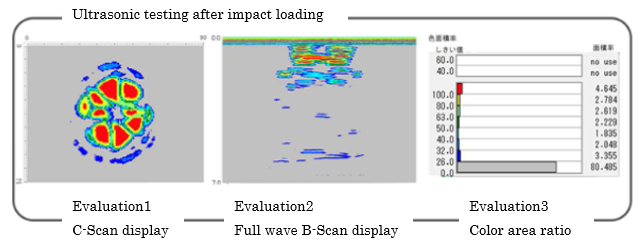

Ultrasonic flaw detection equipment for in-line

In accordance with the wishes of the customer, It is possible to manufacture the equipment according to customer's request.

For example, there are combinations of necessary equipments such as transport method, pallet, various control methods, data management, and mounting of peripheral equipment according to the equipment environment.

Applicable field

- Materials

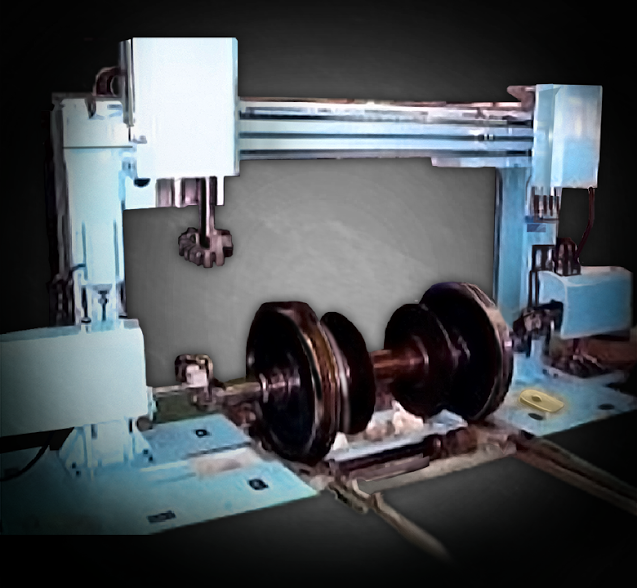

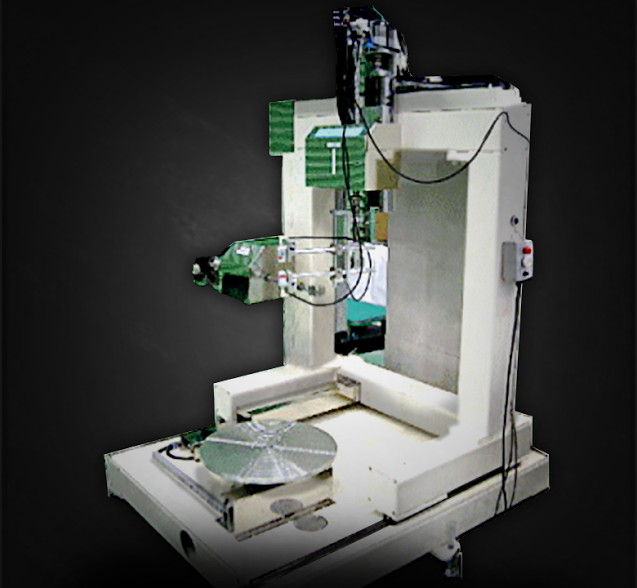

Ultrasonic flaw detection equipment for solid axles (G-AUTO ATMS7)

It detects and visualizes micro cracks occurring in the solid axis.

The shape echo and defect echo can be easily distinguished by automatic judgment, waveform shape judgment and full wave section display function with A-scope memory.

Strength

- High precision positioning

- Maintenance-free drive unit

- In addition, it can be designed to suit the purpose of use.

Applicable field

- Railway

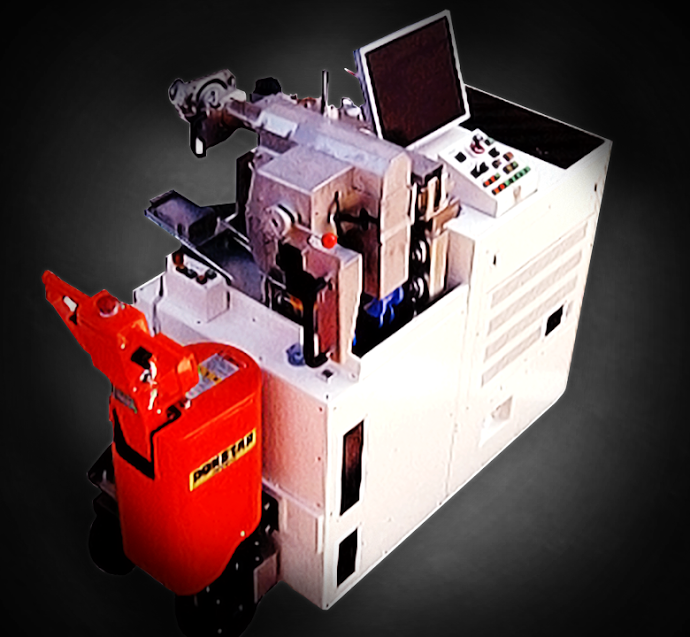

Multichannel ultrasonic flaw detection equipment for hollow axles(Max 8ch)

It detects and visualizes micro cracks occurring circumferential direction and direction of the hollow axle in the inner and outer surfaces of hollow shaft.

High reliable inspection such as automatic sensitivity adjustment, automatic judgment and coupling check function is possible. Furthermore, it has extensive functions that can easily discriminate shape echo and defect echo.

Strength

- Waveform recording of all CH data being detected by the A scope memory function of maximum 8 ch is possible.

- It is possible to use with multiple channels (angle)

- C-scope, B-scope, chart basic display is possible

- High precision positioning

- Maintenance-free of drive unit

Applicable field

- Railway

Ultrasonic flaw detection equipment for hollow axles

It detects and visualizes micro-cracks occurring the outer surface of the hollow axle.

High reliable inspection such as automatic sensitivity adjustment, automatic judgment and coupling check function is possible. Furthermore, it has extensive functions that can easily discriminate shape echo and defect echo.

Strength

- High precision positioning

- Maintenance-free of drive unit

- In addition, it can be designed to suit the application.

Applicable field

- Railway

Material Surface Sound Diagnosis Device (GNES-1001)

Ultrasonic Pulser-Receiver GNES-1001 comes with the software for Material Surface Sound Diagnosis

Utilizing SH wave pulse which is generated in parallel with the surface, property change near surface layer of the material is measured and analyzed non-destructively. Making calibration curve of the amount of surface material change of metal/ceramic/polymer and others together with specific waveform parameters, evaluation of material property can be done, such as hardness, fatigue, membrane thickness, deterioration, crack and others.

Click here to download the brochure (refer to 2nd page).

Measurable parameters

Quench depth, hardness measurement, plating thickness, thermal spray, painted film thickness, metal fatigue, deterioration judgment and so on.

Applicable field

- Materials

Full digital multi-ultrasonic test instrument

It's ultrasonic flaw detector of board type.

The standard is 4 channel, and it can be extended up to 12 channel.

Table

| Output voltage | 400V |

| Reception frequency band | from 0.5MHz to 15 MHz |

| Frequency filter | Broadband / 1.0 / 2.25 / 5.0 / 10.0MHz |

| Setting sensitivity | 80dB (0.1dB Step) |

| Gate | Independent 3 gates |

| Following the gate | S, B , S+B |

| Echo display | RF, full wave, positive half wave, negative half wave |

Applicable field

- Aerospace/Airplane

- Railway

- Automobile

- Materials

- Others

Portable digital ultrasonic test instrument

Our ultrasonic flaw detector has high performance flaw detection function and can be used for a wide range of applications.

Our detector is excellent in portability, usability, high performance, durability. You can move the equipment easily and perform flaw detection at the production site.

Reception Frequency

Standard mode:from 0.5MHz to 30MHz(-3dB)

PA mode:1kHz-10MHz

Strength

- The flaw detector displays defect location, depth, size and shape in the metal and the weld on the screen.

- Even if you are not an expert in the ultrasonic flaw detection test, you can know the situation inside the metal and the weld.

Applicable field

- Aerospace/Airplane

- Automobile

- Materials

- Building materials

- Others

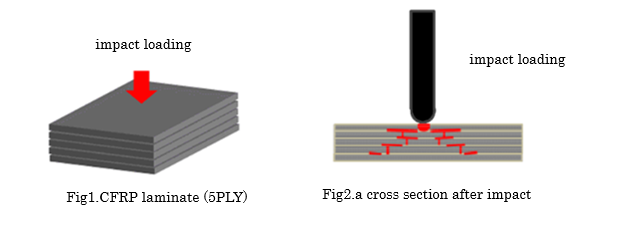

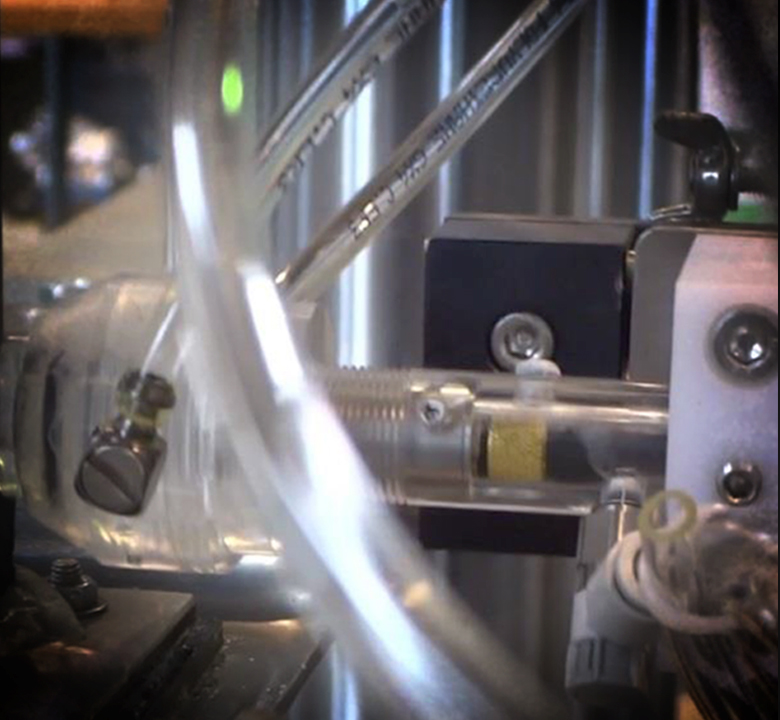

Material load test and ultrasonic flaw detection at the same time (GSCAN-E)

The material load testing system sends the signal of the slight change in material to the scanner of the ultrasonic flaw detector. We can inspect the material destruction starting point by ultrasonic flaw detection directly without a time loss.

Strength

- We can inspect the origin and type of the breakage without removing test pieces from the system.

- We can detect the flaw of test pieces in the material load testing system.

- In addition, it can be designed to suit the purpose of use.

- We use the local water immersion technique by the water nozzle. Our system gives little influence on the test result of the material loading.

Applicable field

- Aerospace/Airplane

- Automobile

- Materials

- Building materials

GSCAN type.Aero.(Air-coupled (Non-contact) ultrasonic flaw detection )

Existing ultrasonic testing methods require contact medium like water to transmit ultrasonic waves to scan objects, but water cannot be used for a scan object for which rust or deterioration is concerned. Using low frequency probes, high power pulser/receivers, signal amplifier and noise filters, air-coupled ultrasonic testing becomes possible without contact medium. Applicable for aero-space craft body and parts made of CFRP, Lithium Ion batteries and others.

Table

| Flaw detection method | Non-contact medium transmission method and reflection method |

| Dynamic range | >140dB(TOTAL) |

| Frequency range | from 50kHz to 5MHz |

| Output mode | Chirp,Pulse,Burst |

| Probe | Transmitter 1, Receiver 1 |

Click here to download the brochure.

Strength

If the material is CFRP within 120mm of thickness, it can detect φ5mm delamination, and if it is adhesive joint of ASSY, it can detect φ7mm unbonded joint.

(It is track record by artificial defect).

Applicable field

- Aerospace/Airplane

- Automobile

- Materials

- Building materials

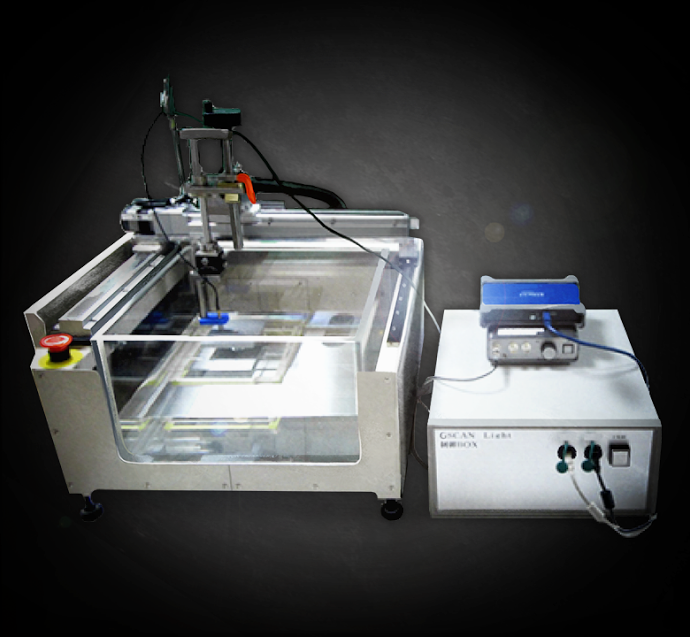

GSCAN Light(Desk scanner)

It is a device for immersion ultrasonic flaw detection with equipment which having X-Y axis, and it can draw a plan view (C-scope) etc. by the signal. It can be to analyze after recording with the function with installed A-scope memory.

Miniaturization and price reduction were achieved comparing with conventional specification.

Strength

- Frequency characteristic: from 0.6 to 80 MHz

- Use laptop(Windows10 compatible)

- A-scope, B-scope and C-scope other display

- The function to record all the points is installed

- 2 gate system, expansion function is installed

Applicable field

- Aerospace/Airplane

- Automobile

- Materials

GSCAN PA(Phased array ultrasonic flaw detection image processing system)

By ultrasonic flaw detection with a phased array, there is an advantage that pitch and focal length can be set electronically by high-speed flaw detection and aperture synthesis.

Therefore, it is more effective for detection of plane and large objects.

Strength

- High precision positioning

- Maintenance-free drive unit

- In addition, it can be designed suit the purpose of use.

Applicable field

- Aerospace/Airplane

- Automobile

- Materials

- Building materials

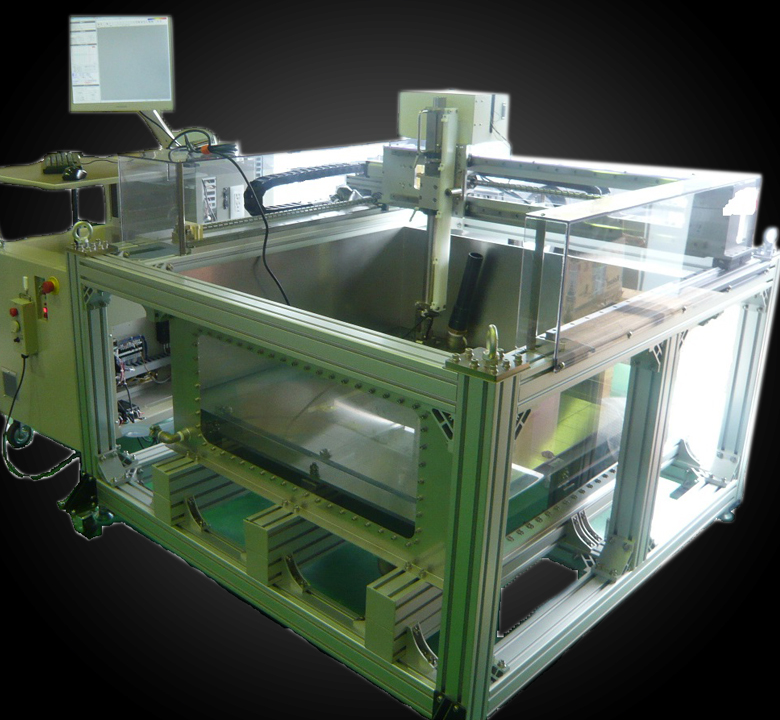

GSCAN Ultrasonic Scanning & Image Processing System

GSCAN , with ultrasonic flaw detection technology, analyzes inner flaw existence without destroying products. To facilitate ultrasound transmission, the target is water

immerged and scanned automatically to illustrate its thickness, flaw position, and uneven distribution of material, etc. GNES, leading the market over tens of years, have developed the software easy to use. With its credited quality, it is widely used for quality control in manufacturing and mobility industries.

Click here to download the brochure.

Strength

- High precision positioning

- Maintenance-free drive unit

- In addition, it can be designed to suit the purpose of use.

Applicable field

- Aerospace/Airplane

- Automobile

- Materials

- Building materials

- Aerospace/Airplane

-

- GSCAN (The scanner that process the image of an ultrasonic flaw detection result)

- GSCAN PA (Phased array ultrasonic flaw detection image processing system)

- GSCAN Light(Desk scanner)

- Air-coupled (Non-contact) ultrasonic flaw detection equipment

- Material load test and ultrasonic flaw detection at the same time (GSCAN-E)

- Portable digital ultrasonic test instrument

- Full digital multi-ultrasonic test instrument

- Ultrasonic SH wave diagnosis and analyzing system for the surface of material (USH-SD/SN)

- Railway

-

- Ultrasonic flaw detection equipment for hollow axles

- Multichannel ultrasonic flaw detection equipment for hollow axles (Max 8ch)

- Ultrasonic flaw detection equipment for solid axles (G-AUTO ATMS7)

- Portable digital ultrasonic test instrument

- Full digital multi-ultrasonic test instrument

- Automobile

-

- GSCAN (The scanner that process the image of an ultrasonic flaw detection result)

- GSCAN PA (Phased array ultrasonic flaw detection image processing system)

- GSCAN Light(Desk scanner)

- Air-coupled (Non-contact) ultrasonic flaw detection equipment

- Material load test and ultrasonic flaw detection at the same time (GSCAN-E)

- Portable digital ultrasonic test instrument

- Full digital multi-ultrasonic test instrument

- Ultrasonic SH wave diagnosis and analyzing system for the surface of material (USH-SD/SN)

- Materials

-

- GSCAN (The scanner that process the image of an ultrasonic flaw detection result)

- GSCAN PA (Phased array ultrasonic flaw detection image processing system)

- GSCAN Light(Desk scanner)

- Air-coupled (Non-contact) ultrasonic flaw detection equipment

- Ultrasonic flaw detection equipment for in-line

- Material load test and ultrasonic flaw detection at the same time (GSCAN-E)

- Portable digital ultrasonic test instrument

- Full digital multi-ultrasonic test instrument

- Ultrasonic measuring system for all elastic model and dilation, shear internal frictions(UMS-R)

- Ultrasonic SH wave diagnosis and analyzing system for the surface of material (USH-SD/SN)

- Building materials

-

- Air-coupled (Non-contact) ultrasonic flaw detection equipment

- Air-coupled (Non-contact) ultrasonic flaw detection equipment (The specification for in-line)

- GSCAN (The scanner that process the image of an ultrasonic flaw detection result)

- Material load test and ultrasonic flaw detection at the same time (GSCAN-E)

- Others

-

- G-Sonic Couplant

- Dry-Coupled Sheet

- Pulsar Receiver (GNES-1001-PR)

- Portable digital ultrasonic test instrument

- Full digital multi-ultrasonic test instrument