- +81-774-95-9701

- Inquiry to us

【Newspaper】 2019/5/1 Our representative Inoue comment was described in “NIKKAN KOGYO SHINBUN(Newspaper)”.

The article about GNES Corporation is published at the corner of “Strength of our company from Kyoto” on “Creative Kyoto M&T (Mar/2018)”.

Our Corporate website has been renewed.

NDT(Non Destructive Testing) is one of typical inspection methods to detect invisible defects, such as cracks and voids, for which normally visual check cannot be done for materials, parts or finished products without being damaged to see inside. It is commonly used in the field of research and development of advanced materials and industrial products.

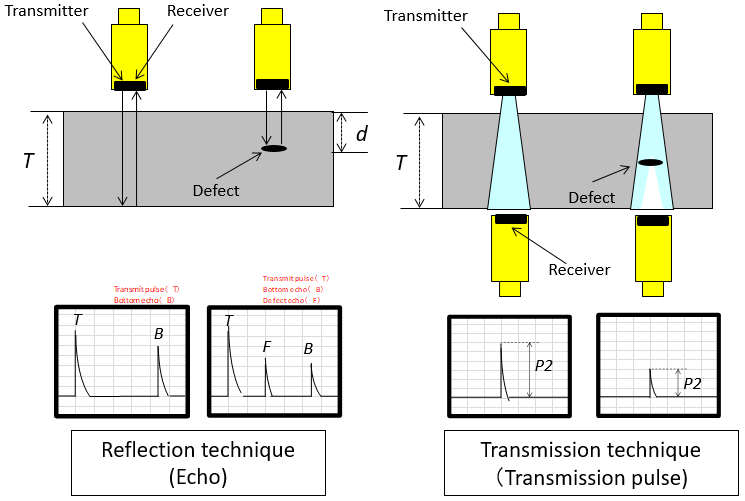

UT (Ultrasonic Testing) is one of Non Destructive Testing methods to detect internal flaws of metals or composite materials etc. by using ultrasonic waves. There are mainly two methods - pulse echo method and through transmission method.

-“Pulse echo method” can highlight the presence, size, shape and depth of the flaws by checking the echo height and its transmission time when ultrasonic pulse is transmitted through inside or underneath of the material and reflection is generated because of acoustic inpedance difference between the boundary of materials or voids and so on.

-“Transmission method”is to send/receive a pulse from the transmitting probe to the receiving probe. The size and shape of the flaws can be highlighted by checking the strength of the transmitted wave, which is decreased when ultrasonic pulse is interferred with flaws inside of the material.

We use 0.1-100MHz range of ultrasonic by detecting defect, and mostly uses 1-10MHz range of ultrasonic for metal materials.

Existing ultrasonic testing methods require contact medium like water to transmit ultrasonic waves to scan objects, but water cannot be used for a scan object for which rust or deterioration is concerned. Using low frequency probes, high power pulser/receivers, signal amplifier and noise filters, GNES have made air-coupled ultrasonic testing available for materials for aerospace or construction without using contact medium (couplant).